Intel Corp. unveiled its next-generation client processor series, the Intel Core Ultra 3 (code-named Panther Lake), the company’s first product built on Intel 18A, its most advanced semiconductor process to date and the first 2-nanometer-class node developed and manufactured in the United States. The launch signals a pivotal step in Intel’s effort to reassert U.S. leadership in chip manufacturing and to anchor the future of computing in domestic innovation.

Panther Lake is designed to power a new generation of AI-enabled PCs, gaming systems, and edge devices, with high-volume production slated to ramp later this year and broad market availability expected in January 2026. Intel also previewed its Xeon 6+ server processor, code-named Clearwater Forest, another 18A-based chip set to debut in the first half of 2026. Both products are being manufactured at Fab 52, Intel’s new high-volume fabrication plant in Chandler, Arizona, which the company calls a key milestone in its $100 billion investment to expand domestic semiconductor production.

“We are entering an exciting new era of computing, made possible by great leaps forward in semiconductor technology that will shape the future for decades to come,” said Intel CEO Lip-Bu Tan. “Our next-gen compute platforms, combined with our leading-edge process technology, manufacturing and advanced packaging capabilities, are catalysts for innovation across our business as we build a new Intel.”

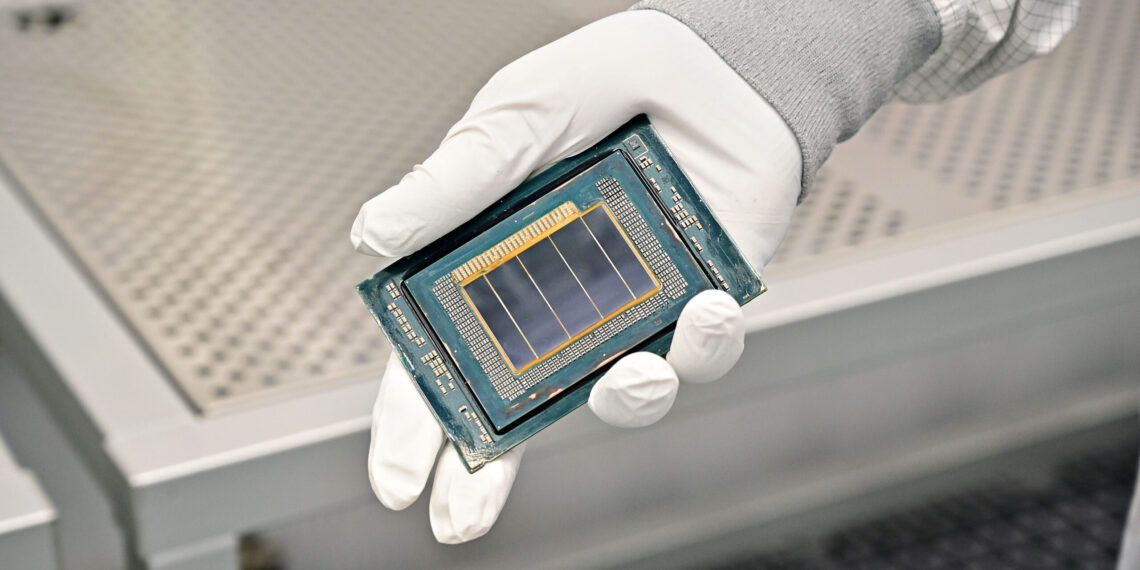

The Panther Lake architecture introduces a scalable, multi-chiplet system-on-chip design built on Intel 18A, offering significant performance and efficiency gains over its predecessor. Intel says the new Core Ultra 3 platform combines Lunar Lake-level power efficiency with Arrow Lake-class performance, delivering up to 50% faster CPU and GPU performance compared to the previous generation. The processor integrates up to 16 performance and efficiency cores, a new Intel Arc GPU with 12 Xe cores, and AI acceleration of up to 180 platform TOPS—a figure that positions it among the most AI-capable consumer chips ever developed.

The new architecture will extend beyond personal computing into edge and robotics applications. Intel introduced an AI Robotics software suite and reference board designed to enable rapid development of cost-effective robots using Panther Lake for control and perception, signaling the company’s push into embedded intelligence across industries.

Complementing its client-side advancements, Intel’s Clearwater Forest, branded Xeon 6+, is built entirely on Intel 18A and marks the company’s most efficient data center processor to date. The chip integrates up to 288 efficiency cores, delivering a 17% uplift in Instructions Per Cycle (IPC) over the prior generation while achieving major gains in density, throughput, and energy efficiency. The Xeon 6+ is aimed at hyperscale data centers, cloud providers, and telecommunications networks, offering the ability to scale workloads, lower energy costs, and drive performance across AI and cloud-native services.

At the heart of both products lies Intel 18A, the company’s most advanced semiconductor node, representing a leap in transistor design and power delivery. Developed at Intel’s Oregon R&D hub and now entering high-volume manufacturing in Arizona, Intel 18A delivers up to 15% better performance per watt and 30% improved transistor density compared to Intel 3. The node introduces two major breakthroughs: RibbonFET, Intel’s first new transistor architecture in more than a decade, enabling superior scaling and energy efficiency; and PowerVia, a backside power delivery system that enhances signal integrity and power flow.

Intel’s Foveros 3D packaging technology further integrates multiple chiplets into advanced system-on-chip designs, enhancing scalability and performance while enabling a flexible platform for future generations. Intel said the 18A node will serve as the foundation for at least three upcoming generations of client and server products.

Fab 52, located at Intel’s Ocotillo campus in Chandler, represents the centerpiece of Intel’s renewed U.S. manufacturing strategy. The facility is the company’s fifth high-volume fab in Arizona and produces the most advanced logic chips ever made on U.S. soil. Together with advanced R&D in Oregon and packaging operations in New Mexico, Intel is positioning itself to offer a fully integrated, U.S.-based semiconductor supply chain—a move aligned with national efforts to strengthen domestic technology leadership and reduce dependency on overseas foundries.

With Panther Lake and Clearwater Forest, Intel is signaling its return to the leading edge of semiconductor innovation.