ScioSense, a Netherlands-based maker of sensor ICs and modules, introduced a new low-power ultrasonic flow sensing module designed to support multi-year battery life in industrial and consumer applications. The module, called UFM-02, aims to simplify the integration of ultrasonic flow measurement and leak detection in devices where power cabling is limited or unavailable.

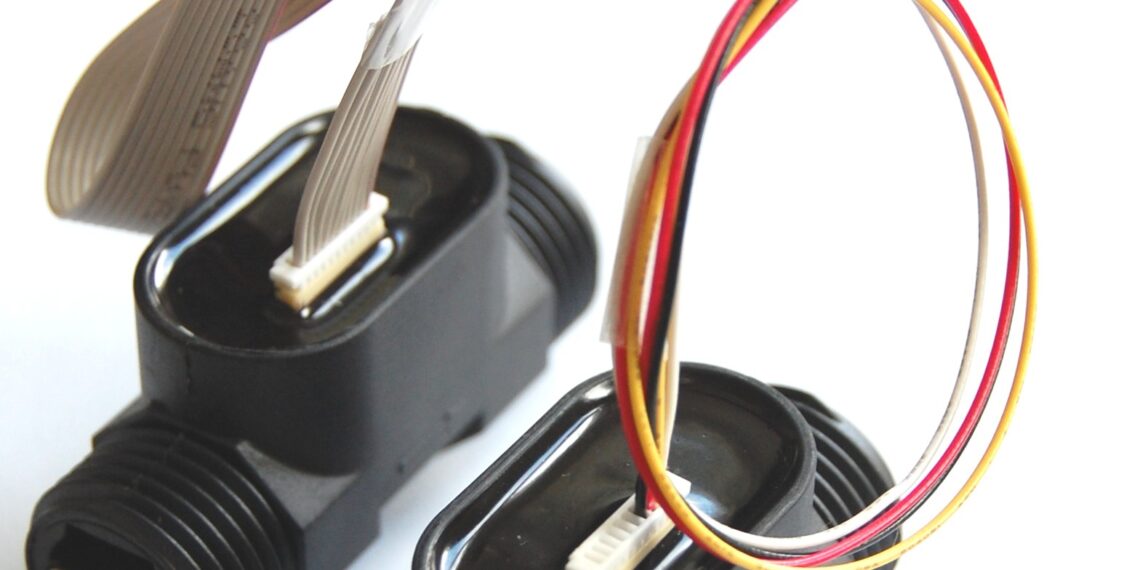

The launch, announced Tuesday in Eindhoven, marks an expansion of the company’s ultrasonic sensing portfolio. Building on its earlier UFM-01 unit, the UFM-02 integrates a sensor board, spool piece, a pair of ultrasonic transducers and a precision measurement circuit based on a ScioSense flow converter chip. The company said the system arrives fully calibrated and ready for deployment.

A key upgrade is its average operating current of 50 microamps, a reduction that allows equipment manufacturers to design products capable of running for several years on a standard primary battery. The power profile positions the UFM-02 for use in segments where manufacturers seek to eliminate cabling to reduce installation complexity or improve design flexibility.

ScioSense said the module is suited for a wide range of flow-measurement and leak-detection tasks, including in food-grade systems. Potential applications span water purifiers, dispensers, boilers, heat pumps, coffee machines, smart toilets, taps, irrigation equipment and agricultural systems, along with swimming pools, spas and cooling infrastructure. In industrial settings, the module can track total liquid volume through filters, enabling maintenance schedules based on usage rather than fixed intervals.

The UFM-02 is being introduced with two thread options: 0.5-inch (13.3 mm ID) and 1-inch (23.7 mm ID). The company plans to expand the lineup to include 3/8-inch (11.2 mm ID) and 1.5-inch (36.3 mm ID) versions. Flow capacity ranges from 20 liters per minute in the smallest configuration to 450 liters per minute in the largest.

ScioSense emphasized that its ultrasonic sensing approach avoids the mechanical components found in traditional turbine-based flow meters. The absence of rotating parts supports longer operating life and improves reliability, particularly in systems exposed to continuous or fluctuating flow rates. The design also enhances sensitivity to weak flows, enabling leak detection at levels as low as 0.03 liters per minute in the smallest thread size.

The module supports two connection options: a four-wire pulse interface for simple pulse-based output, generating up to 450 pulses per liter, and a 10-wire SPI interface that delivers digital data including total flow volume in cubic meters, filtered flow rate in liters per hour, and liquid temperature. This gives device makers flexibility in choosing between minimal integration requirements and deeper data access.

“With a truly low-power implementation of ultrasonic flow sensing, this technology becomes accessible to a new range of applications,” said Andreas Blocherer, Senior Product Manager at ScioSense. The ability to operate on battery power without external cabling, he added, enables manufacturers to embed flow measurement and leak detection “anywhere,” improving efficiency, reliability and cost management in liquid-handling systems.