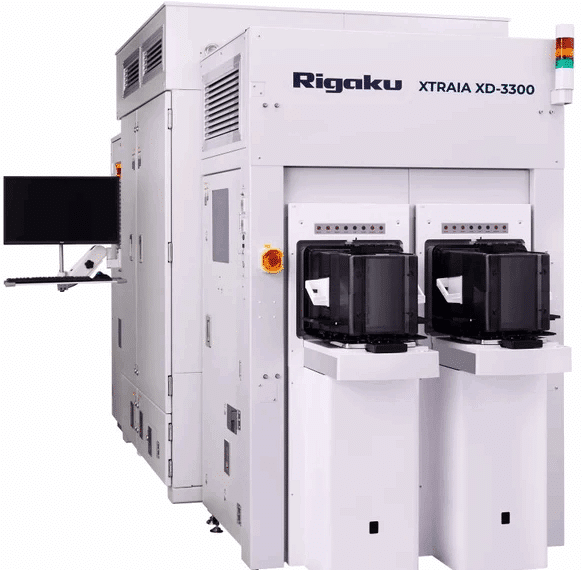

Rigaku Corporation, a leading Japanese developer of X-ray metrology systems, has launched mass production of its XTRAIA XD-3300, a high-resolution microspot X-ray diffraction system aimed at supporting next-generation semiconductor fabrication, the company said on Tuesday.

The launch comes amid soaring global demand for high-performance semiconductors driven by generative AI applications and the expansion of hyperscale data centers. In response, chipmakers are rapidly advancing toward more complex architectures, including 3D DRAM, high-bandwidth memory (HBM), and 2-nanometer (nm) logic chips. These technologies increasingly rely on superlattice structures made using silicon/silicon-germanium (Si/SiGe) processes, where precise control of material composition and film thickness is critical to product performance and yield.

Rigaku said the XTRAIA XD-3300 is the only commercially available system capable of direct, non-destructive diffraction measurements of superlattice structures on microscopic wafer pads with high resolution. The system is designed entirely in-house, including the X-ray optics, detection system, and diffraction software.

“The XTRAIA XD-3300 represents the crystallization of Rigaku’s leading-edge technologies,” said Kiyoshi Ogata, Senior Executive Vice President and Product Division General Manager. “We have already delivered systems to multiple leading-edge semiconductor manufacturers and expect broader adoption as next-generation chip production scales up.”

A key innovation in the XD-3300 is its proprietary X-ray optical system, which uses ultra-high-performance mirrors and bent crystals to increase measurement speed by up to 100 times compared to previous models. Measurements that once took hours can now be completed in minutes, significantly enhancing production throughput.

Additionally, Rigaku’s advanced software enables quantitative analysis of periodicity and boundary surface quality in complex multilayer structures—capabilities vital for both R&D and high-volume manufacturing of cutting-edge memory and logic chips.

Rigaku said it has expanded its production capacity to support commercial rollout, including the construction of a new facility and the addition of 15 manufacturing booths. The company forecasts sales of over JPY 1 billion (USD 6.9 million) for the XD-3300 in fiscal year 2025, with ambitions to grow that figure to JPY 10 billion (USD 69 million) by fiscal year 2030.

The XD-3300 system is expected to play a key role in enabling quality control for next-generation semiconductor devices as manufacturers adopt increasingly intricate nanoscale designs.